Commercial Services

We’ve got the solution for your need. Reach out today to start a conversation on how we can complete your project with the highest quality products at the best price!

Ballpark Pricing…

We always prefer to custom quote because each job can be very unique in it’s own right, but these are some very basic ballpark prices.

Residential Flooring

$5.50/sq ft

Epoxy Flake Flooring

$6.75/sq ft

Metallic Flooring

Commercial Moves

$6.00/sq ft

Epoxy Flooring

$7.50/SQ FT

Metallic Flooring

Partner Program

$4.50/sq ft

Epoxy Flake Flooring

$6.25/sq ft

Metallic Flooring

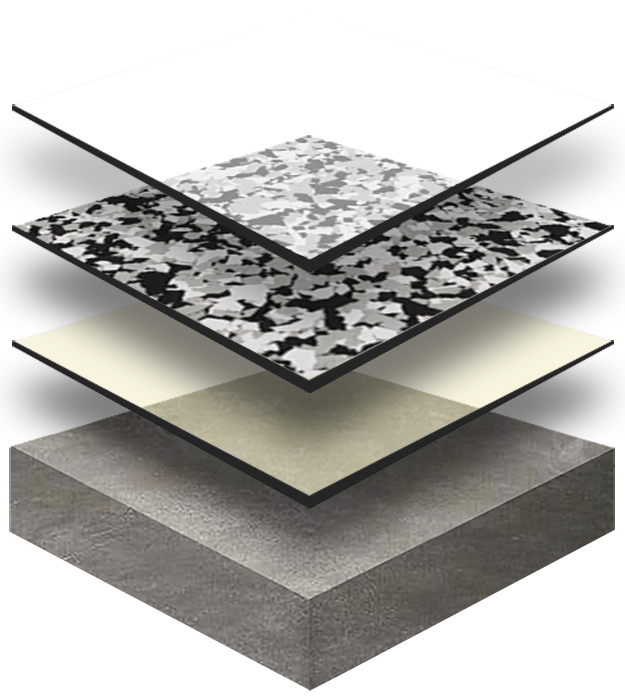

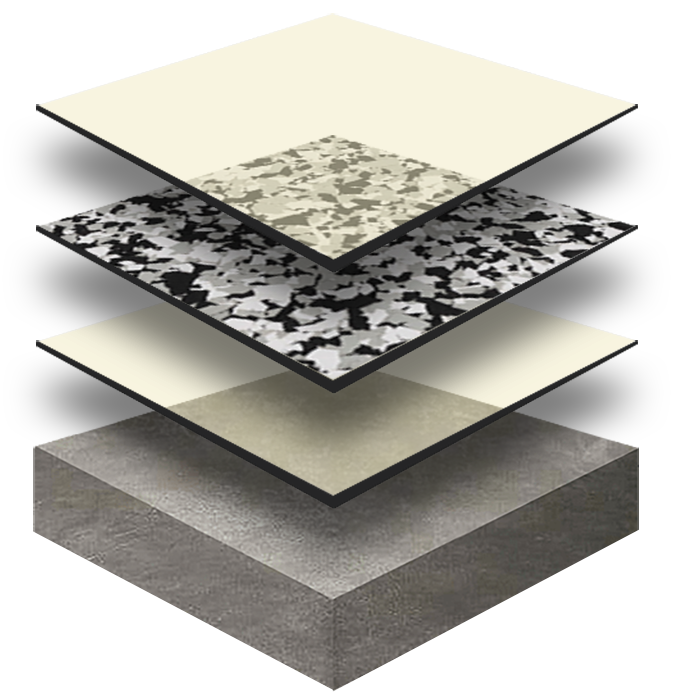

At Epoxy & Sealing Systems, Inc., we believe in doing things the right way, even if it means a slightly higher cost. Our commitment to quality is reflected in our meticulous application process, as shown in the cross-section image to the right. Starting with your concrete base, we apply a layer of epoxy for superior bonding (binds to concrete better than Polyurea/Polyaspartic), followed by a evenly broadcasted flake layer for texture and durability. Finally, we seal it with a polyurea/polyaspartic top coat, known for its hardness and UV resistance to prevent yellowing where exposed to sunlight.

This method ensures the highest end results providing a long-lasting, chip-resistant finish. Rest assured that when working with Epoxy & Sealing Systems that we never compromise on quality to cut costs.

In contrast to our approach, many companies opt for Epoxy as the top layer, likely due to its lower cost or lack of expertise. This method, however, can lead to issues like yellowing, especially in sun-exposed areas, as Epoxy is not as UV-resistant. Moreover, it's not as hard as Polyurea or Polyaspartic coatings, making it less durable. We've seen some companies even combine the base coat, flakes, and top coat in a single layer application, skip the cleaning and grinding prep, and a host of other bad practices. While this may be fine for temporary situations, flips, or other scenarios where cost is a priority over quality, this is not advisable and not how things are done by us.

At Epoxy & Sealing Systems, Inc., we don't cut corners or compromise on quality. Our commitment is to provide superior, long-lasting results without sacrificing performance for cost.

Get A Free Estimate

Our Services is Simple & Effective…

We know the most effective way to do things, and we replicate that each and every time ensuring a successful application for every project.

Concrete Repair & Prep

We thoroughly clean and diamond grind the surface as well repair any damaged areas in preparation for the epoxy.

Base Coat

An even and thick layer of epoxy base coat is applied in one sweeping motion binding to the concrete surface below.

Aggregate Application

The flake or aggregate of your choice is broadcast evenly across the entire surface while the epoxy base coat is still wet.

Top Clear Coat

A UV-resistant polyurea top clear coat is applied providing the hardness and durability you want from your new floor.

Get in Touch

Open Hours

8am - 6pm (Mon-Sat)